3D printing, also known as additive manufacturing, has revolutionized how we create and prototype objects. Once restricted to industrial use, advancements in technology have brought 3D printing into the hands of hobbyists, educators, and consumers. This guide delves into the world of consumer 3D printers, exploring their types, how they work, and how to get started with this fascinating technology.

There are several types of 3D printers available for consumers, each with its own unique technology and capabilities. Understanding these types and their variations can help you choose the right printer for your needs.

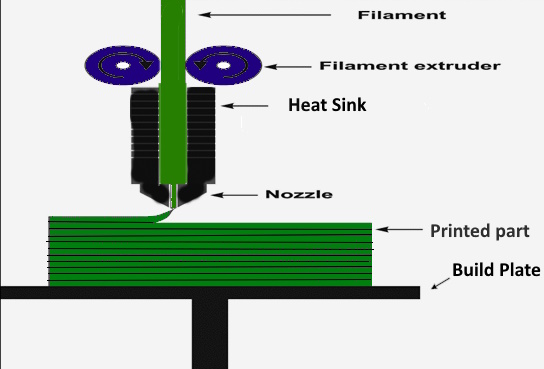

FDM printers are the most common type of consumer 3D printers. They work by extruding heated thermoplastic filament through a nozzle, layer by layer, to create an object. They are popular for their affordability and ease of use, making them ideal for beginners.

FDM printers come in different varieties:

Materials used in FDM printers include PLA, ABS, PETG, and TPU. Each material offers different properties, such as flexibility or strength, allowing for a variety of applications.

Metal-infused PLA is a composite filament containing metal powders mixed with PLA. These filaments allow hobbyists and professionals to create parts that mimic the appearance and weight of metal without needing specialized equipment. Metal-infused PLA is typically available in bronze, copper, or stainless steel varieties.

While the prints are not solid metal, they can be post-processed to achieve a metallic finish. Sanding, polishing, or even tumbling the parts can bring out the luster of the embedded metal particles. This type of filament is ideal for creating decorative items, jewelry, or prototypes that require the feel of metal.

For truly solid metal parts, sintering the printed object in a kiln can fuse the metal particles, removing the PLA binder. However, this process requires additional equipment and expertise, making it more suitable for advanced users.

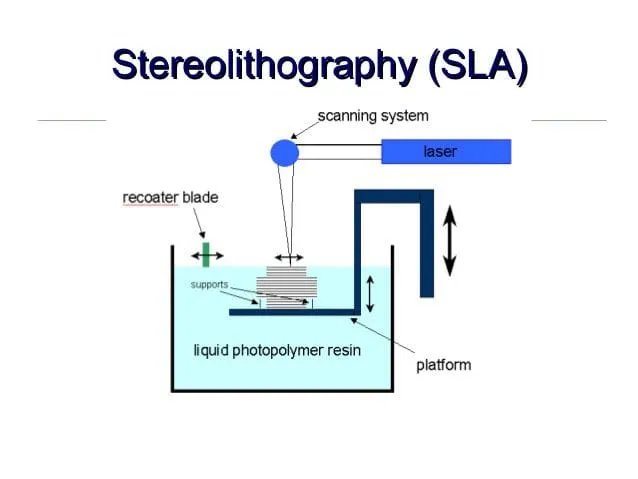

SLA printers use a liquid resin that is cured layer by layer using a UV laser or light source. These printers are known for producing highly detailed and smooth prints. However, they require post-processing, such as washing and curing the printed objects, and the resin can be more expensive than FDM filament.

SLA printer variations include:

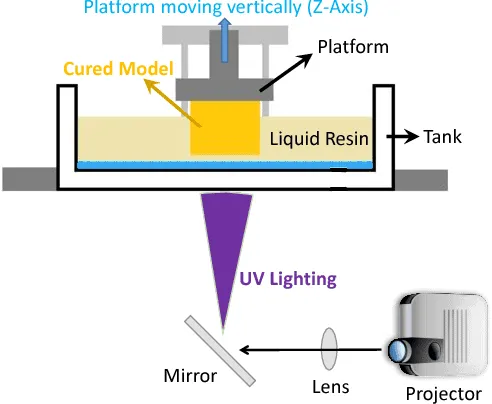

Similar to SLA, DLP printers use light to cure liquid resin. Instead of a laser, they use a digital light projector to cure an entire layer at once. This makes them faster than SLA printers while maintaining high detail and resolution.

DLP printer variations include:

SLS printers use a laser to fuse powdered materials such as nylon or polyamide. They are not as common in the consumer market due to their high cost but are becoming more accessible. SLS printers produce durable and complex parts without needing support structures.

SLS printer variations include:

SLS technology can also be used with metal powders such as stainless steel, titanium, or aluminum to create metal parts. The laser sinters the metal powder layer by layer, creating fully functional, solid metal parts with excellent durability and precision. This capability makes SLS ideal for industries requiring high-performance components.

Industries currently leveraging SLS metal printing include aerospace, automotive, and medical sectors. For example, aerospace companies use it to produce lightweight, high-strength components for aircraft, while the medical industry creates customized implants and surgical tools. Automotive manufacturers use SLS metal printing for prototyping and producing end-use parts with complex geometries.

An SLM printer refers to a Selective Laser Melting printer. It is a type of 3D printer that uses a high-power laser to fully melt and fuse metal powders into solid, dense metal parts. SLM technology is widely used in industrial applications where high-strength, lightweight, and highly detailed metal parts are required.

1. Metal Powder Layering: A thin layer of metal powder (e.g., aluminum, titanium, stainless steel) is spread across the build platform.

2. Laser Melting: A laser precisely melts and fuses the metal powder in the desired pattern for each layer.

3. Layer-by-Layer Build: The process repeats layer by layer until the part is completed.

4. Post-Processing: Once the build is finished, the part may require support removal, heat treatment, or surface finishing.

SLM is extensively used in industries where precision and material properties are critical:

- Produces fully dense, high-strength metal parts.

- Allows for complex geometries, including internal channels and lattice structures.

- Reduces material waste compared to traditional manufacturing methods.

- Cost: SLM machines and metal powders are expensive, making them less accessible for consumer use.

- Speed: The process can be slow for large parts due to the layer-by-layer melting.

- Post-Processing: Requires additional steps such as support removal and heat treatment to finalize parts.

SLM is considered one of the most advanced metal 3D printing technologies and is primarily used in industrial settings where performance and material integrity are paramount.

Regardless of the type, most 3D printers follow a similar workflow:

If you're new to 3D printing, the following steps can help you get started:

Consider your needs, budget, and the type of projects you plan to work on. FDM printers are great for beginners due. Check out our top 5 Carbon Fiber Printers to learn more. to their affordability and versatility. If you need high detail or smooth finishes, SLA or DLP printers might be better options.

Familiarize yourself with 3D modeling software. Many free options, like TinkerCAD are user-friendly and great for beginners. Learning basic design principles will help you create custom objects.

Mastering printer settings is crucial for successful prints. Common settings include layer height, print speed, and temperature. Start with the recommended settings for your printer and materials, and experiment as you gain experience.

3D printing involves a learning curve, and troubleshooting is part of the process. Be patient and take the time to understand your printer's quirks. Online communities and forums are excellent resources for advice and support.

3D printing opens up endless possibilities for creativity and problem-solving. Here are a few applications:

While 3D printing is incredibly versatile, there are challenges to consider:

Consumer 3D printing is an exciting and rapidly evolving field. Whether you're a hobbyist, prepper, DIYer, educator, or entrepreneur, the ability to turn digital designs into physical objects offers endless possibilities. With a bit of patience and practice, anyone can unleash their creativity and start exploring the world of 3D printing.